I always find it a bit inefficent to build humanoid robots to replace humans at a task. They’re very complex and slow. Why not spend the money and rethink the task ie. warehousing already has been automated as well as a lot of things in manufacturing.

Don’t get me wrong this is very cool to see but I can’t think of many use cases for this.

I agree. It seems like a lack of creativity trying to solve the problem of a “general purpose” robot.

Now we just need to have them do the overcomplicated task of connecting a brain to it (including feedback) and handling the biological needs of said brain (oxygen, nutrition, immune, etc) and we’ll have gone full circle. That is assuming the utility of that tech will not ever be largely outpaced by AI.

The idea of making humanoid shapes is to provide more general flexibility for various tasks rather than a robot specialized for just one thing. It’s the same reason for the goal of AGI vs. lots of narrow AI. There is a loss of effectiveness because of that, but the adaptability and universal nature perhaps could make up for it. It’s true that doing it just because it’s new might not always be the best solution. Other tools can be used as a hammer, but sometimes it’s better to use the tool designed for the task rather than have one tool that does everything.

I mean, sure, but what is the point of legs unless you’re using stairs, ladders, or uneven terrain?

Make its bottom half a forklift design. It gets more height variance and it’s simpler to maintain and build. The tech ain’t here yet.

If having flexibility is overkill for the job, then you’re correct, as well as keeping it simpler. But look at Boston Dynamics’s Spot and how many special purpose jobs it has been applied to by many companies. I recently saw a video about some electrical work that’s dangerous and how they worked with BD to train the robot to be able to adapt to situations and remove operators from being there entirely. And there are other companies with their own version of Spot (although they don’t seem to be quite as cutting edge).

If you have a basic warehouse setup and all the things being picked are similar, then a more basic automated picker certainly makes sense. Some places need more than that, so they use humans, or if something comes along that makes more sense than humans (for good or bad reasons) they’ll use the new tech.

To add on what others of said.

Part of its being able to stick it anywhere and a lot of things are built with the human body/arms in mind (not boxes obviously).

Do something stupid simple like getting grocery carts, it can have a hand that would be good enough or build a special gripper/mover that can have problems if some things change

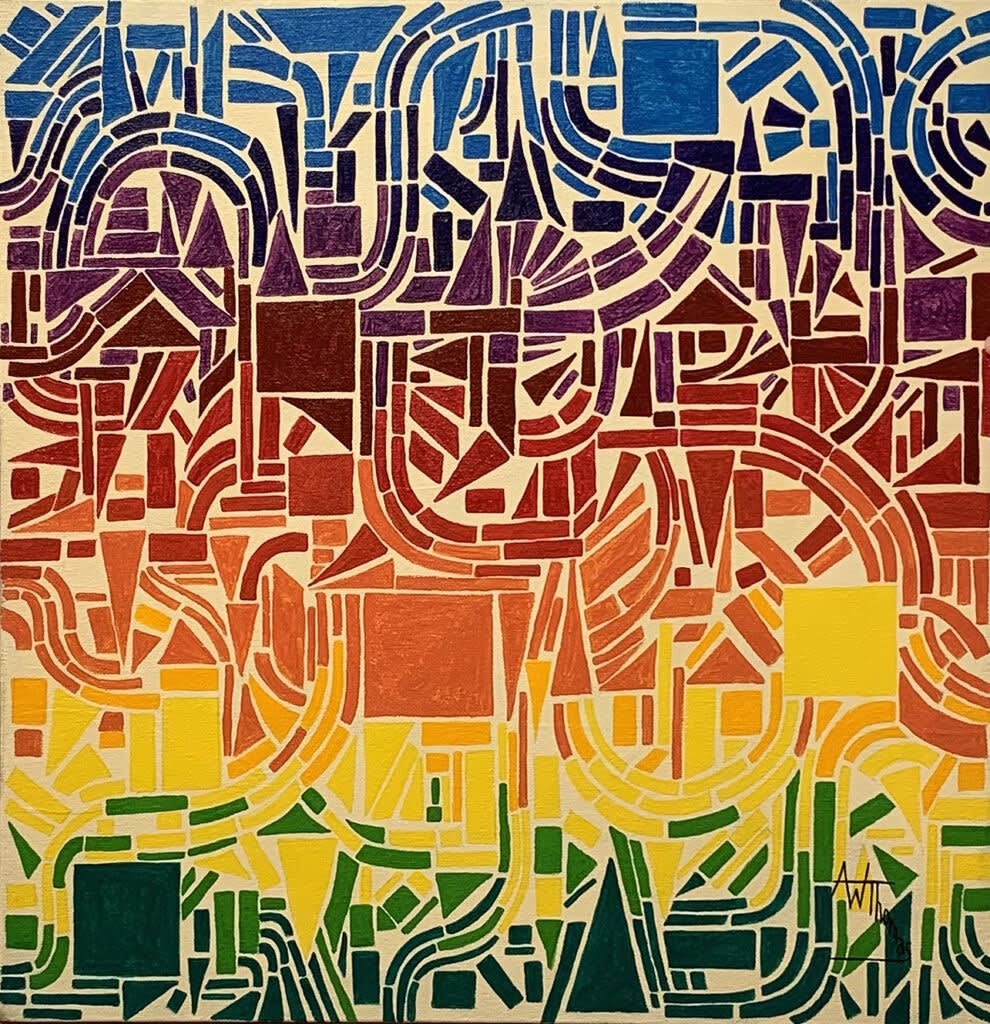

Here’s a video showing this model of robot in action.

It will be interesting to see what capabilities these have, and how trainable they will be. They look like they can do simple warehouse work, but will they be much more capable than that?

I hope they cover the legs with something to prevent kids from pinching their fingers in that reverse knee joint area.

Uh oh! if your job is slowly taking a box from a shelf semi-successfully, you better watch out!

The growth of capabilities will likely be exponential. Small box today, larger box tomorrow, exterminating all human lifeforms by Thursday, relax on Friday as robot overlords have instituted a 4 day work week.

Ahh that will be nice to finally relax

I work in an environment like that. The bar is very low, it wouldn’t take much to beat some humans at the job. Plus the robots can work 24/7 and don’t (yet) complain about stuff. No HR or OSHA needed either.